Study Precision: Materials Test Lab Precision Unleashed

Wiki Article

From Concept to Fact: The Value of Materials Testing in Item Development

On the planet of product growth, the trip from principle to fact is a complicated and detailed procedure. One critical facet that commonly goes undetected however plays a crucial role is materials screening. Products screening is the organized evaluation and examination of the residential or commercial properties and habits of various materials made use of in product growth. It includes defining product requirements, conducting toughness and longevity testing, evaluating chemical composition and compatibility, and analyzing security and efficiency requirements. By subjecting products to extensive testing, item designers can make the most of product quality, reliability, and ultimately, consumer contentment. This post checks out the value of products screening in item advancement and highlights its relevance subsequently ingenious ideas right into substantial, successful products.Defining Product Needs

To define material needs precisely, detailed study and analysis are essential. The item advancement group must think about elements such as mechanical properties, chemical sturdiness, cost-effectiveness, and compatibility. They need to also take right into account any kind of regulative or safety standards that the product needs to meet.

Among the vital purposes in specifying product requirements is to determine materials that can stand up to the awaited stress and anxieties and pressures the product will certainly experience throughout its lifecycle. This includes thinking about elements such as temperature level changes, direct exposure to moisture or chemicals, and mechanical forces. By picking materials that can stand up to these problems, the item's efficiency and long life can be optimized.

Moreover, defining material demands also involves thinking about the aesthetic and responsive qualities of the materials. The visual appeal, appearance, and feel of the product play a significant function in its marketability and individual experience.

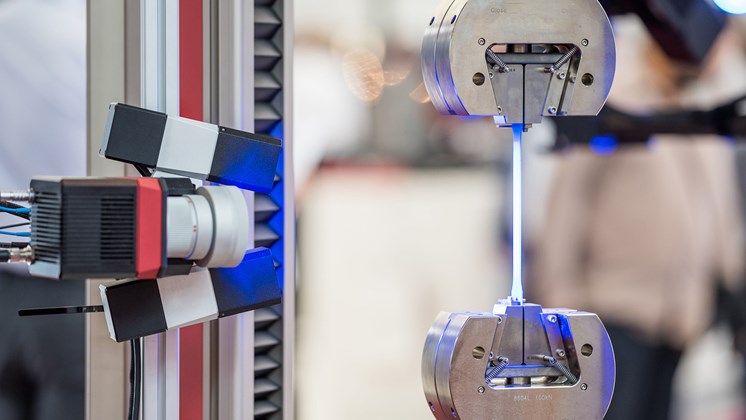

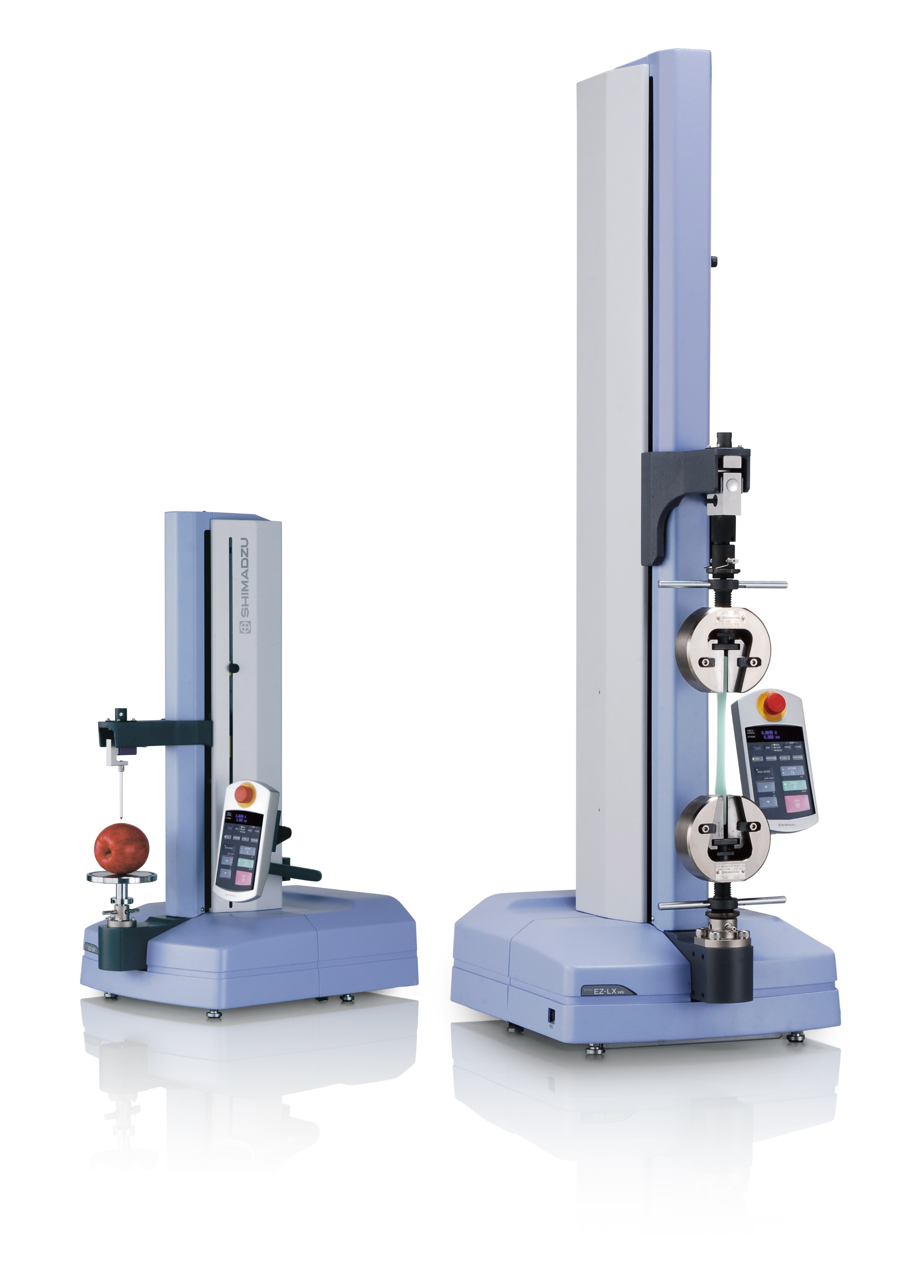

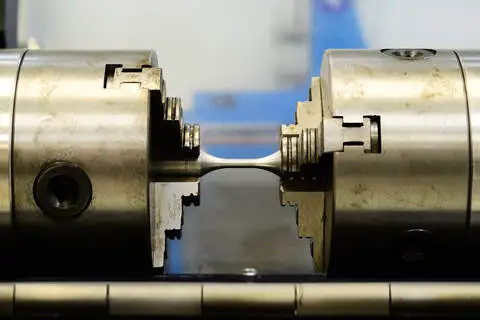

Carrying Out Strength and Longevity Testing

To make sure the reliability and long life of a product, carrying out stamina and resilience testing is important in the item development procedure. This sort of testing enables producers to recognize exactly how a product will execute under various problems and stress and anxiety levels, helping them make informed choices about style alterations and product options.Strength screening includes subjecting a product to regulated pressures to establish its capability to withstand tons and stress. This can be done via examinations such as tension, compression, bending, and torsion tests. By measuring the item's response to these pressures, engineers can assess its structural honesty and determine any type of weaknesses or possible failing points.

Reviewing Chemical Composition and Compatibility

Chemical make-up and compatibility assessment is a vital action in the product advancement process as it enables manufacturers to evaluate the suitability of materials for their intended applications. Recognizing the chemical makeup of a material is necessary to guarantee that it fulfills the needed requirements for capability, performance, and safety.Throughout the assessment procedure, manufacturers assess the chemical make-up of materials to establish their properties, such as resistance, resilience, and strength to corrosion. This information aids in selecting one of the most suitable products for details applications, as different products may have varying chemical compositions that influence their performance.

Compatibility assessment is similarly essential, as it guarantees that the products made use of in a product are compatible with each other and with any type of various other substances they may come right into contact with. Conflict can result in chain reactions, deterioration, and even failure of the item.

To our website examine chemical compatibility, makers perform tests to mimic real-world problems and examine how different products connect. These tests may consist of direct exposure to various temperatures, pressures, and chemicals. The results of these tests help producers recognize any possible problems and make notified choices concerning material option and style adjustments.

Assessing Safety and Efficiency Criteria

Makers have to extensively examine safety and performance standards to guarantee the top quality and integrity of their items. The evaluation of safety requirements entails evaluating the item's capability to run securely and without presenting any dangers to customers. This consists of evaluating whether the item satisfies industry-specific safety laws and requirements, along with conducting tests to identify prospective threats and dangers. Performance requirements, on the various other hand, concentrate on assessing the product's ability to satisfy specific efficiency standards and specifications. This involves testing the product under various problems to ensure that it performs as anticipated and fulfills the demands of the designated users. By analyzing security and performance requirements, makers can determine any possible issues or imperfections in their items and take the required actions to address them. This not just aids in making certain the safety of customers however also boosts the overall top quality and reliability of the items. It is important for manufacturers to invest in extensive screening and analysis processes to develop trust fund with their clients and maintain their track record in the marketplace.

Making The Most Of Product Top Quality and Integrity

By making certain the detailed analysis of security and efficiency criteria, producers can effectively make the most of the high quality and reliability of their products. Making the most of item top quality and integrity is critical for organizations to acquire an one-upmanship and keep client satisfaction - materials test lab. To attain this, manufacturers must utilize extensive screening approaches throughout the product advancement procedureOne vital element of maximizing item top quality and reliability is performing detailed products testing. This entails evaluating the homes and qualities of the materials used dig this in the manufacturing of the product. By examining the products for elements such as longevity, stamina, and resistance to ecological problems, producers can recognize prospective weak points and make essential renovations to enhance the overall high quality and integrity of the item.

Furthermore, makers ought to likewise think about using advanced testing techniques, such as non-destructive testing (NDT) NDT enables the assessment of a product's integrity without triggering damages, ensuring that the quality and dependability of the product are not endangered during the screening procedure.

Moreover, suppliers should constantly review the performance and check of their products in real-world conditions. This can be done with field screening and celebration feedback from clients. By collecting and examining data on item performance, manufacturers can determine locations for enhancement and make needed adjustments to enhance the quality and reliability of their products.

Final Thought

To conclude, materials testing plays a vital role in item growth by guaranteeing that the materials used meet the needed demands for stamina, resilience, chemical structure, compatibility, performance, and safety standards. By conducting extensive testing, makers can optimize the top quality and reliability of their items - materials test lab. It is important to prioritize products examining throughout the growth process to make certain the effective understanding of concepts right into substantial itemsMaterials screening is the systematic exam see post and assessment of the residential properties and actions of numerous materials utilized in item advancement. By subjecting materials to extensive testing, item developers can maximize item top quality, dependability, and ultimately, client satisfaction.One of the essential objectives in defining material needs is to identify materials that can hold up against the awaited anxieties and stress the item will experience throughout its lifecycle. By accumulating and evaluating data on product efficiency, producers can determine areas for renovation and make required adjustments to improve the top quality and dependability of their products.

In conclusion, products testing plays a vital role in product growth by making certain that the products used fulfill the required demands for strength, sturdiness, chemical structure, efficiency, compatibility, and safety criteria.

Report this wiki page